T Series Three-phase Synchronous Motor

View The Model by Dragging Mouse

Overview

The T series Large AC Three-phase Synchronous Motor for sinter machine is the core driving equipment in steel and metallurgy industries, which is the main product of our company since founded in 1950. This series motor has excellent performance in dragging large inertia load capacity, so it has been widely used in petro, petrochemical and power plant industries in dragging heavy inertia machines like blower, water pump and compressor etc.

with our sixty to seventy years of experience in manufacturing medium and large high-voltage AC motor. By using advanced technique comprehend from domestic and abroad, after modern field-circuit electromagnetic calculation and optimized design on dissipation, ventilation circuit and windage resistance, component intensity of the motor, our products are high efficiency, low noise, low vibration, high reliability and easy to install and maintain.

Fig:The first 6300 kW synchronous motor in China made by Shenyang Motor Factory in 1968.

| rated voltage: | 3kV~11kV motors series with multiple voltage grades. The motor can be started directly at full voltage or soft start at a lower voltage. |

| power range: | 1000-12000kW |

| Pole number: | 6,4 |

| speed: | 1000,1500r/min |

| frame size: | 1730,1430,1180 |

| frenquecy: | 50,60Hz,frequency conversion |

| cooling method: | IC37,IC81W |

| protection grade: | IP44,IP54,IP55 |

| mounting: | IM7311 |

| standards: | IEC,GB; The electric motor can be divided into drilled shaft motor and non-drilled shaft motor, the drilling shaft motor need to be applied with air clutch, while the non-drilling motor has higher starting ability. |

| At rated voltage: | Starting torque ratio 1.0 Pull-in torque ratio 0.8 Pull-out torque ratio 2.0 Starting current ratio 7.0 |

The outdoor series (W), humid tropics series (TH), humid tropics outdoor series (THW) motor performance index, installation and volume dimension are the same as the basic series motor that they are derived from.

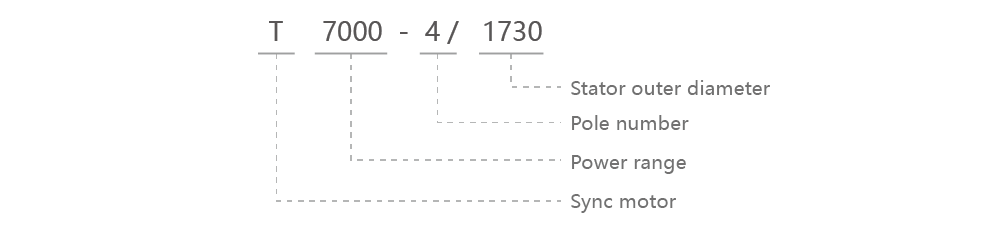

Type introduction

|

|

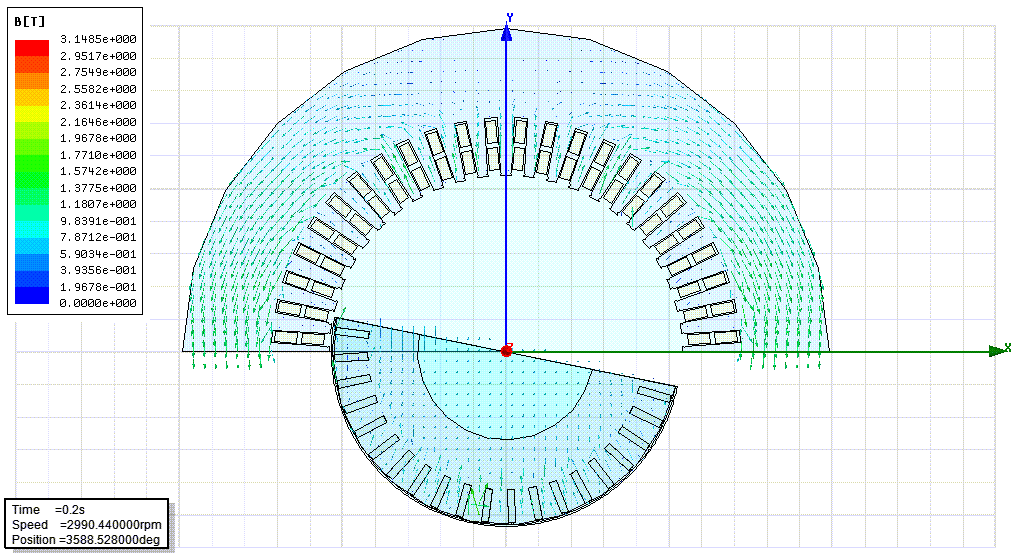

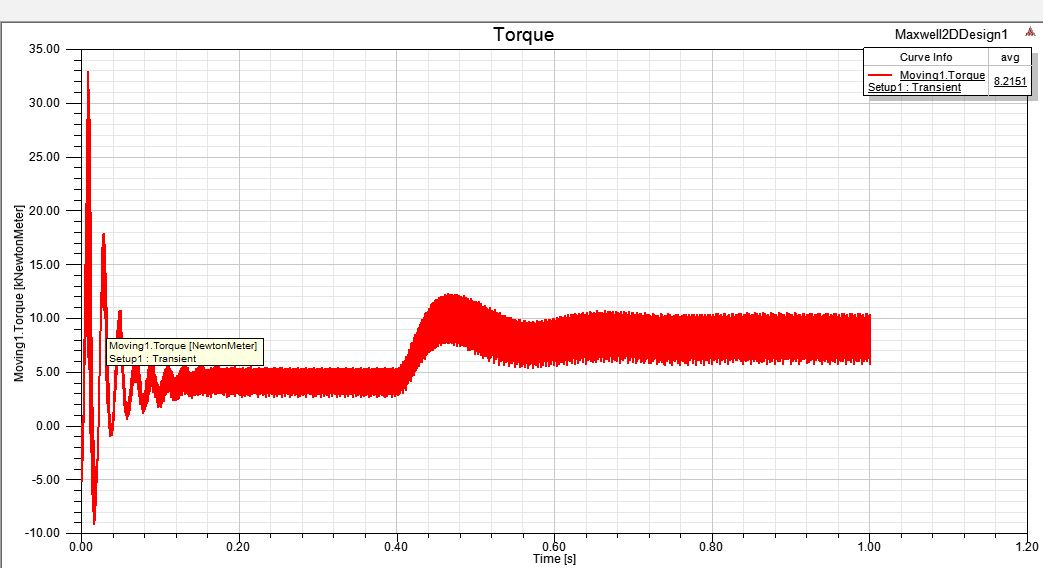

| Electromagnetic diagram by using field-circuit coupling | Output curve by electromagnetic calculation |

|

|

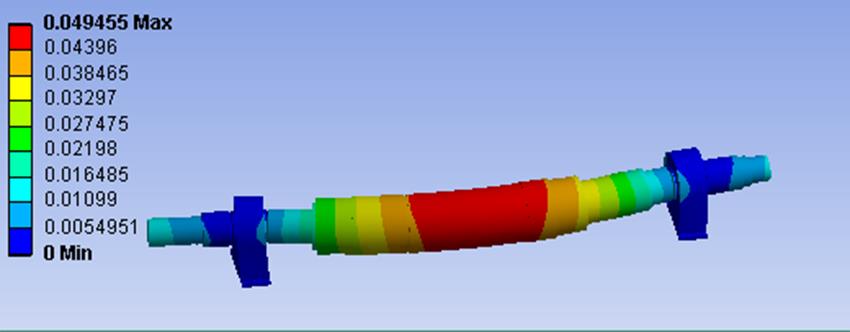

| Shafting analysis | |